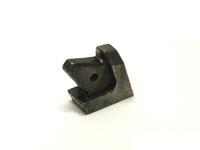

We have been casting ductile iron products since 1951 and have probably manufactured parts similar to yours in the past. With all of our castings, we have complete traceability from raw material to finished lot. Each lot includes samples that go to a 3rd party lab for testing.

Processes

Sand Cast: Shell molding and Resin Sand molding. These are the most common method of cast iron products.

Materials

Ductile Iron: Grade 65-45-12 (the most common)

Ductile Iron: Grade 60-40-18

Ductile Iron: Grade 80-55-06

Malleable Iron: Grade 32510 per ASTM A-47

Gray Iron: Grade 20-25

Sizes

We can cast small ductile iron parts that weigh only a few ounces, as in our small wing nuts or large ductile iron parts up to 90 lbs, as the type used on construction & earth-moving equipment.