History

Started in 1951 in Columbia, PA, we are a 3rd generation, family-owned manufacturing business dedicated to providing our customers with high quality, custom metal components.

In 1999, Peerless Hardware opened their 2nd manufacturing facility in China. The China factory provides raw castings to our Pennsylvania factory where we do machining, finishing and final inspection.

We also use our China facility to provide our customers with low-cost value added services such as assemblies, kits and other labor-intensive products where costs have to be kept at a minimum.

Today, brothers and co-owners, James and Peter Speitel carry on the manufacturing excellence that their family started 3 generations ago.

Custom Metal Components for OEM production is the majority of our work but we also have a diverse product line that we manufacture and inventory for sale.

Our Main Product line for sale, includes the following:

Hand Fasteners:

Since 1951, we manufacture and inventory a product line of hand-fasteners such as wing screws, wing nuts, thumb screws and handle nuts which are cast. This provides an oversized surface area for ease of assembly & disassembly by hand. Our wing screw and thumb screw products offer some of the longest lengths in the industry. You can find our products in industrial supply catalogs such as Grainger, Fastenal, McMaster Carr, MSC, and others.

Blocks/Pulleys, Snaps & Misc. Industrial Hardware and Marine Hardware

Our unique line of directional pulleys include zinc plated, wire/rope pulleys with Cast (not stamped) bodies which give a thicker, heavy-duty body. Our best selling Wheel Hoists are manual wire/rope pulleys with safe working load capacities of at least 1,000 lbs.

Custom Manufacturing:

Most of our business is custom metal components according to any of the processes below.

Our Manufacturing Processes:

Castings, Forgings, Die Castings, Welding, Stampings.

Materials:

Castings Iron: Ductile Iron, Gray Iron, and Malleable Iron. Investment Cast Steel – Low Carbon Steel, Medium Carbon Steel, Stainless Steel (303, 304, and 316) in lost wax molds.

Minimum Quantities:

We can accept your blanket PO for annual quantity and then ship monthly releases to you. This way your company can receive the best volume discount without having to take delivery of your entire year’s usage. Depending on material, size and weight of the part, here are some guidelines to minimum “annual” quantities;

Welded Parts Average Minimum: 500 pieces annually

Cast Iron Parts Average Minimum: 1,500 pieces annually

Cast Steel Parts Average Minimum: 1,500 pieces annually

Forgings Average Minimum: 2,000 pieces annually

Die Castings Average Minimum: 5,000 pieces annually

Stamped Parts Average Minimum: 5,000 pieces annually

Engineering:

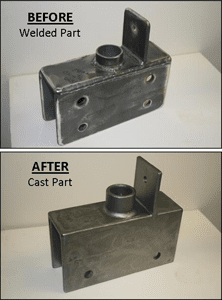

If you have a part but do not have a technical drawing (print), we can reverse-engineer a technical drawing from your sample. Many times, an OEM is using a weldment in production where a cast part would be much more cost-efficient. The more touches to the weldment (bending, stamping, punching, welding, etc) the more savings will be realized by switching to a cast part.

Not only does this usually provide significant cost savings but it also produces a higher quality part as the casting mold will make a dimensionally consistent part each time and there are no welds to break.